Transform YourWood ProcessingWith Advanced Kiln Technology

Unlock superior wood quality, faster drying times, and energy efficiency with our revolutionary dehumidifier-based wood seasoning plants.

Why Leading Wood Industries Choose Tripti

Our revolutionary technology transforms the wood seasoning process, delivering unprecedented quality and efficiency.

Faster Drying Time

Reduce drying cycles by up to 60% compared to traditional methods, dramatically improving production efficiency.

Precision Moisture Control

Achieve precise moisture content levels with our advanced sensors and automated control systems.

Energy-Efficient Technology

Our dehumidifier-based systems consume up to 40% less energy than conventional kilns while delivering superior results.

Crack & Warp Prevention

Sophisticated algorithms and precise environmental control virtually eliminate wood defects during seasoning.

Customised Solutions

Tailor-made seasoning plants designed to match your specific wood types, production needs, and facility constraints.

Fully Automated Process

Zero human interaction required throughout the entire wood seasoning cycle, reducing labor costs and human error.

Transforming Wood Industry Challenges

Our revolutionary approach eliminates the common problems faced by wood processors, delivering superior results every time.

Inconsistent Drying Quality

Traditional methods result in uneven moisture content, causing significant product rejection and quality issues.

Excessive Energy Consumption

Conventional kilns waste energy through inefficient heating and poor environmental control systems.

Long Production Cycles

Slow drying times create production bottlenecks, limiting output and increasing carrying costs.

Labor-Intensive Monitoring

Constant manual oversight required, increasing labor costs and introducing human error into the process.

Precision Moisture Equilibrium

Our advanced sensors achieve uniform moisture content throughout each piece of wood, eliminating quality inconsistencies.

Energy-Recycling Technology

Our dehumidifier systems use thermal energy, reducing consumption by up to 40% while improving results.

Accelerated Drying Cycles

Optimized airflow and moisture extraction reduces drying time by up to 60%, dramatically increasing throughput.

Fully Autonomous Operation

Set-and-forget intelligence eliminates human monitoring while providing real-time data and alerts to your devices.

Revolutionary Technology Behind Our Systems

Discover the innovative features that make our wood seasoning plants superior to traditional methods.

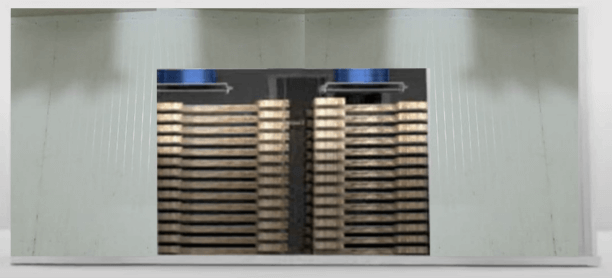

Advanced Dehumidifier-Based Kiln Control System

Intelligent Moisture Sensing Network

Our proprietary sensors continuously monitor moisture content throughout the chamber, ensuring uniform drying across all wood pieces.

Adaptive Climate Control Algorithm

Machine learning-enhanced software that automatically adjusts temperature, humidity, and airflow based on real-time wood response, ensuring optimal drying conditions.

Heat Recovery Dehumidification

Our innovative system captures heat generated during the dehumidification process, dramatically reducing energy consumption while maintaining ideal drying conditions.

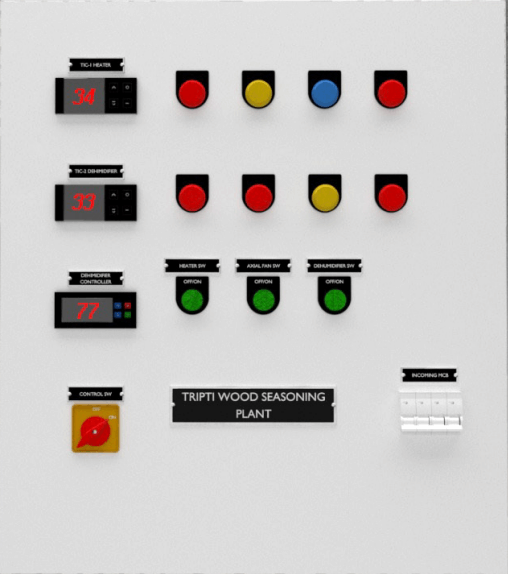

Control Panel Monitoring

Access kiln performance data and even make adjustments from the adjacent control panel.

Structural Options For Every Need

Customize your wood seasoning plant to perfectly match your specific requirements and space constraints.

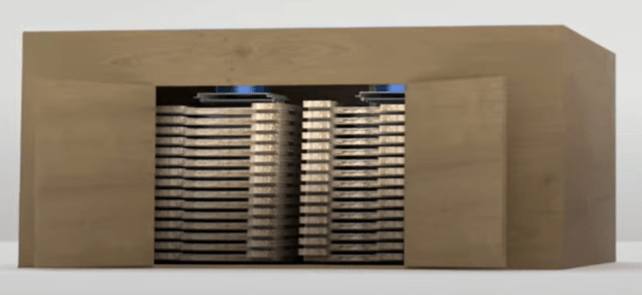

Wooden Structure

Traditional appearance with modern internal technology. Perfect for integration with existing wooden buildings.

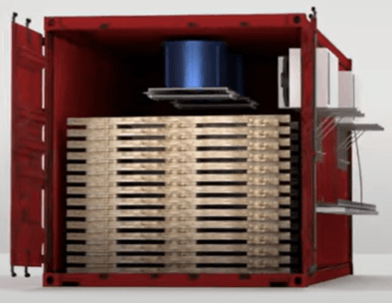

Container Structure

Portable solution that can be easily relocated. Ideal for operations that require flexibility in location.

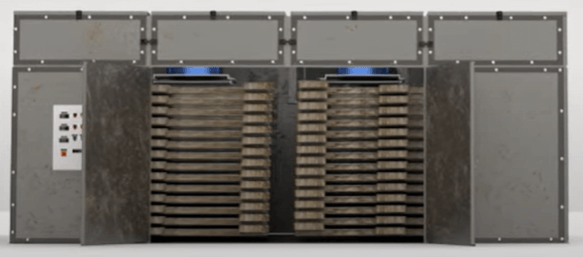

Sheet Metal Structure

Durable, long-lasting construction for permanent installations. Offers excellent weatherproofing and security.

Puff Panel Structure

Superior insulation properties for optimal energy efficiency. Ideal for extreme climate conditions.

Trusted by Leading Wood Industries

Hear from businesses that have revolutionized their wood processing with our advanced seasoning technology.

"Tripti's wood seasoning plant has been a game changer for our furniture manufacturing business. We've reduced drying time by 50% while achieving superior quality. The automated process has virtually eliminated human error and allowed us to focus on our craftsmanship."

Mr Bheesham Sethi

Managing Partner, INDEVA, Ambala, Haryana

"The energy efficiency of Tripti's system has been remarkable. We've seen a reduction in energy costs compared to our old kiln, and it's been the best investment we've made for our wooden handicraft business. The precise moisture control has significantly reduced rejected pieces."

Mr Joseph

R.L. Khanna & Co, Noida, UP

"Their kiln drying chambers have transformed our production. Wood quality has improved, and energy costs have decreased significantly. Tripti's customised plant design perfectly fits our space constraints while delivering exceptional results. The ROI was achieved in just 6 months."

Mr Sirajuddin Shah

Ethos Wood Industries, Greater Noida, UP

Limited-Time Technology Upgrade Offer

Save up to 10% on our latest wood seasoning technology when you schedule a consultation before offer validity expires*

- Free monitoring system upgrade

- Complimentary 1-year maintenance package

- Priority installation scheduling

*Offer applies to new customers only.

Specialised Wood Seasoning for Every Industry

Our technology is tailored to meet the unique requirements of various wood processing sectors.

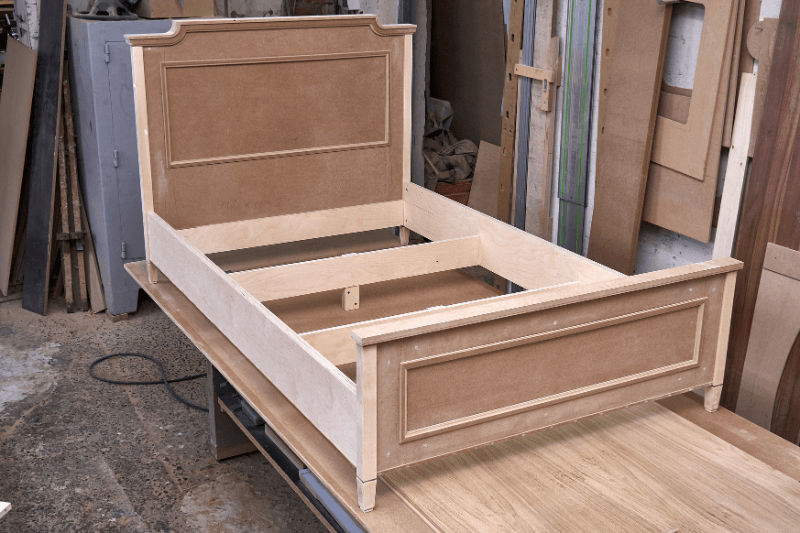

Furniture Manufacturers

- Precise moisture content for lasting quality

- Minimized warping and cracking

- Enhanced glue adhesion and finish quality

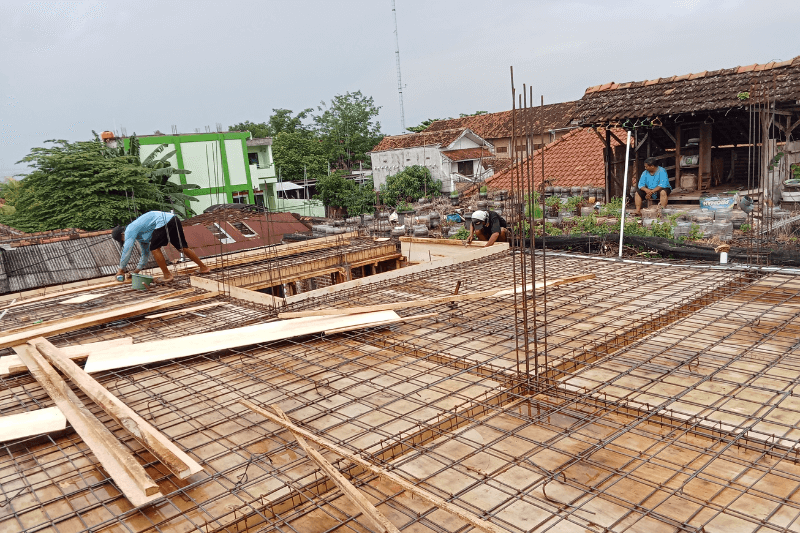

Construction & Infrastructure

- Dimensional stability for structural elements

- Enhanced strength and load-bearing capacity

- Improved pest and decay resistance

Sawmills & Lumber Yards

- High-volume processing capability

- Reduced inventory holding time

- Consistent quality across different wood species

Plywood & Veneer Industry

- Optimal moisture levels for lamination

- Enhanced veneer quality and appearance

- Superior bonding and adhesive performance

Sports Equipment Industry

- Precise moisture balance for optimal performance

- Enhanced durability and impact resistance

- Specialised programs for cricket bats and hockey sticks

Custom Woodworking

- Specialised programs for exotic and rare woods

- Small-batch processing capability

- Preserves natural wood characteristics and beauty

Our Seamless Implementation Process

From initial consultation to finished installation, we ensure a smooth journey to wood seasoning excellence.

Consultation & Needs Assessment

Our experts work with you to understand your specific wood processing requirements, space constraints, and production goals.

- Wood types and volumes

- Facility layout and space availability

- Energy requirements and constraints

- Quality standards and specifications

Custom Solution Design

Based on your requirements, we design a tailored wood seasoning plant with the optimal structure, size, and technology configuration.

- Detailed technical specifications

- Visualization of the plant

- Energy consumption estimates

- ROI and efficiency projections

Manufacturing & Pre-Assembly

We meticulously manufacture all components of your wood seasoning plant, conducting rigorous testing before delivery.

- Component-level testing

- System integration verification

- Control software validation

- Energy efficiency training

On-Site Installation & Setup

Our experienced technicians handle the complete installation process, ensuring minimal disruption to your operations.

- Structure assembly

- Equipment installation

- Control system integration

- Utility connections

Commissioning & Training

We thoroughly test the system, optimize settings for your specific wood types, and train your staff on operation and maintenance.

- System operation procedures

- Control interface navigation

- Maintenance protocols

- Troubleshooting essentials

Ongoing Support & Service

Our relationship continues with comprehensive after-sales support, regular maintenance, and performance optimization.

- Hassle-free technical assistance

- Regular maintenance

- Software updates

- Performance optimization consulting

The Tripti Triple Guarantee

We stand behind our wood seasoning technology with industry-leading guarantees that ensure your complete satisfaction and peace of mind.

Performance Guarantee

If your Tripti wood seasoning plant fails to achieve the specified drying times and moisture content levels, we'll upgrade your system at no cost until performance targets are met.

5-Year Durability Promise

Our plants are built to last. We offer a comprehensive 5-year warranty on structural components and a 3-year warranty on all electronic and mechanical systems.

Energy Savings Guarantee

We guarantee our systems will deliver the specified energy efficiency. If your energy consumption exceeds our projections in the first year, we'll refund the difference.

100% Satisfaction Guarantee

If you're not completely satisfied with your Tripti wood seasoning plant within the first 90 days, we'll make it right or refund your investment.

Still have questions about our guarantees? Contact our experts for detailed information.

30+ Years of Excellence in Wood Seasoning Technology

Since our founding in 1992, Tripti has been at the forefront of wood seasoning innovation, continuously evolving our technology to deliver superior results for the wood processing industry.

Pioneer in Dehumidifier Technology

We were among the first in India to develop and perfect dehumidifier-based wood drying technology, establishing new standards for energy efficiency.

1,000+ Installations

Our systems have been successfully implemented in over 1,000 facilities across India and Nepal, spanning various wood processing industries.

Award-Winning Innovation

Recipient of multiple industry awards for technological innovation, energy efficiency, and contributions to sustainable manufacturing practices.

Experience

Installed

Served

Awards

Mr Amit Khanna

Founder & CEO

"Our mission has always been to combine traditional wood craftsmanship with cutting-edge technology. Every Tripti seasoning plant embodies this philosophy, ensuring wood reaches its fullest potential."

Everything You Need to Know

Get answers to the most frequently asked questions about our wood seasoning technology and implementation process.

How does your technology compare to conventional kilns?

Our dehumidifier-based technology offers several advantages over conventional kilns:

- 40-60% faster drying times without quality compromise

- Up to 40% reduction in energy consumption

- Significantly reduced defect rates (cracking/warping)

- Fully automated operation vs. manual monitoring

- More precise moisture content control

What is the typical return on investment?

Most of our clients achieve full ROI within 8-12 months, depending on their production volume and the specific wood types being processed.

Key factors contributing to this rapid ROI include:

- Increased throughput from faster drying cycles

- Reduced energy costs

- Lower labor costs through automation

- Decreased product rejection rates

- Higher quality finished products commanding better prices

What space requirements are needed for installation?

Our systems are highly adaptable to various space constraints. The minimum area requirements depend on your production volume:

- Small capacity: 250-500 sq. ft.

- Medium capacity: 500-1,000 sq. ft.

- Large capacity: 1,000+ sq. ft.

We offer modular designs that can be customized to fit unusual spaces or be installed in phases as your production grows. Our pre-installation consultation includes a thorough site assessment to ensure optimal placement.

How long does installation and setup take?

The timeline from order to operational status typically follows this schedule:

- Design and manufacturing: 4-6 weeks

- Delivery: 1-2 weeks (depending on location)

- On-site installation: 1-2 days for small to medium plants; 3-4 days for larger installations

- Testing and calibration: 2-3 days

- Training and handover: 1-2 days

Our experienced installation teams work efficiently to minimize disruption to your ongoing operations. For urgent needs, we offer expedited installation services.

What wood types and species can be processed?

Our systems are versatile and can effectively season virtually all commercial wood types with customised drying programs for each species:

Hardwoods:

- Teak

- Mahogany

- Oak

- Walnut

- Maple

- Sheesham

Softwoods:

- Pine

- Cedar

- Spruce

- Fir

- Hemlock

The intelligent control system automatically adjusts drying parameters based on the specific characteristics of each wood type, ensuring optimal results regardless of species.

What ongoing maintenance is required?

Our systems are designed for minimal maintenance requirements:

- Daily: Simple visual checks (automated alerts eliminate the need for constant monitoring)

- Monthly: Basic cleaning and filter inspection

- Quarterly: Comprehensive system check by your maintenance staff (we provide detailed checklists)

- Annual: Professional service visit from our technicians

We offer comprehensive maintenance packages with priority service response and preventive maintenance to ensure optimal system performance throughout its lifespan.

Still have questions? Our wood seasoning experts are ready to help.

Request Your Custom Wood Seasoning Solution

Complete this form to receive a personalised consultation, detailed quote, and ROI analysis for your wood processing needs.

By submitting this form, you agree to our privacy policy and consent to be contacted regarding our wood seasoning solutions.

Why Request a Consultation?

Personalised Solution

Get a customised wood seasoning plant designed specifically for your production requirements and facility constraints.

Detailed ROI Analysis

Receive a comprehensive breakdown of expected returns, energy savings, and production improvements.

Priority Scheduling

Consultation requests are placed in our priority queue for faster response and implementation.

Limited-Time Offer

Access special pricing and complimentary upgrades available only to consultation requesters.

"The consultation process was incredibly valuable. Tripti's experts identified efficiency opportunities we hadn't even considered. The resulting system has transformed our production capacity."

— Sachiv Dhawan, Automotive Solutions, Delhi